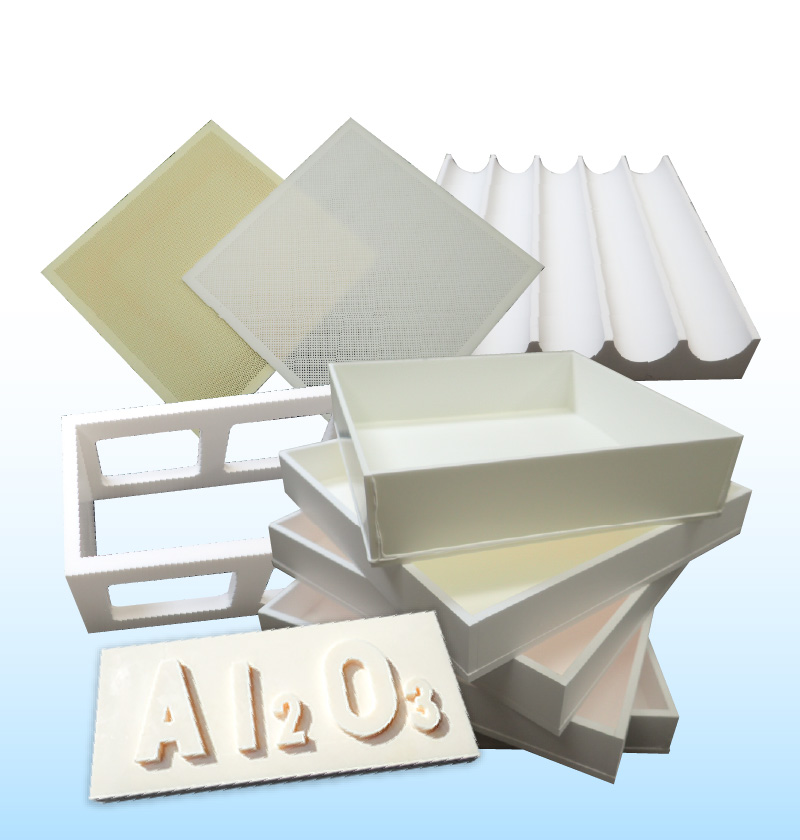

Our firing jigs are available in a wide variety of materials to suit your product needs. In electronic ceramic items like MLCC and thermistors, our setters are highly rated by a wide range of customers for their stable quality, excellent thermal shock, and high temperature deformation properties.

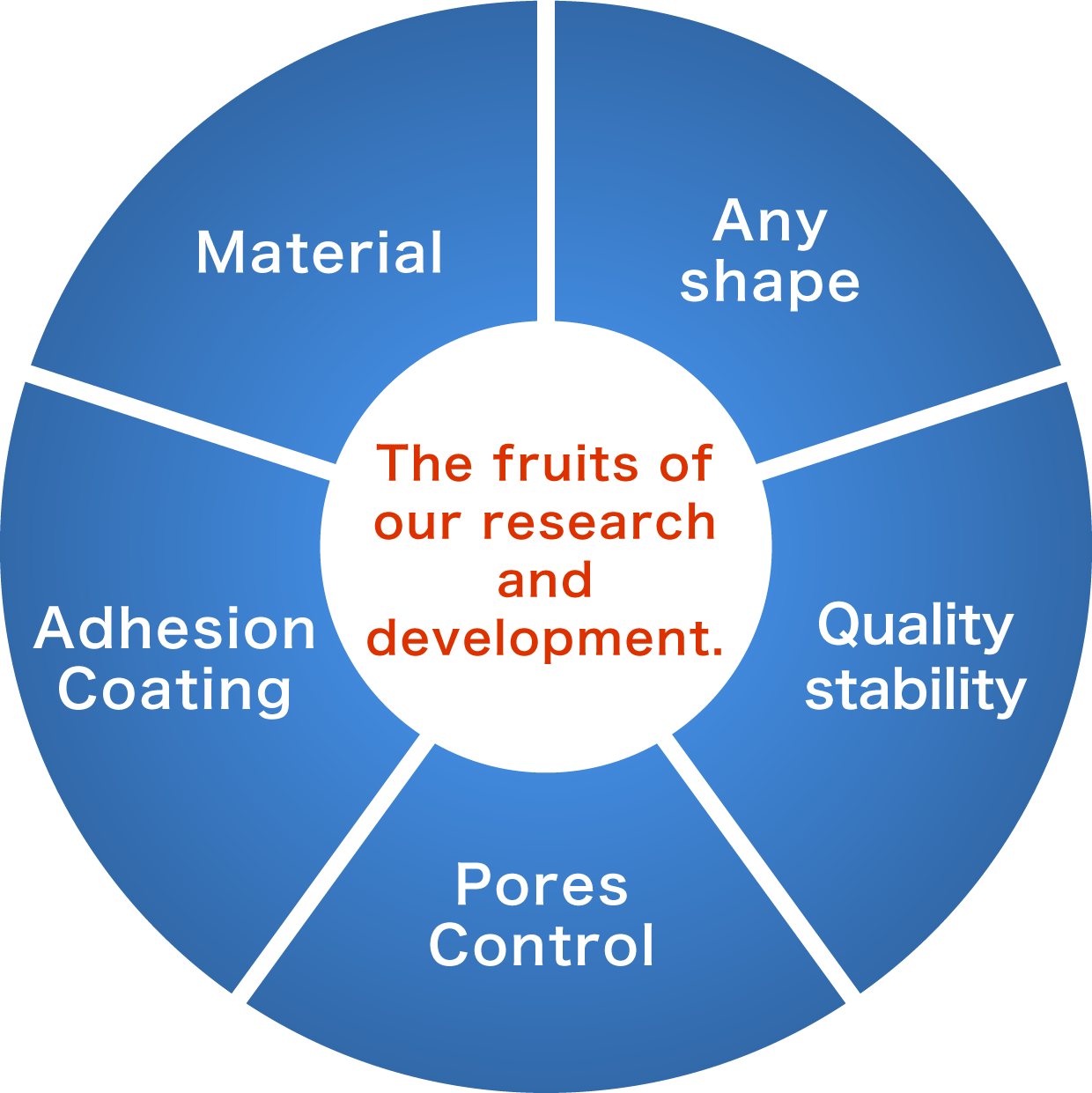

We also offer firing jigs with different compositions and porosities to meet to customer requirements.

In particular, the multi-hole setter, which accommodates special shapes and high debindingabilities, has revolutionized sintering technology.

We also offer firing jigs with different compositions and porosities to meet to customer requirements.

In particular, the multi-hole setter, which accommodates special shapes and high debindingabilities, has revolutionized sintering technology.

We have a wide range of products from dense bodies to porous bodies,

including alumina, mullite, zirconia, cordierite, yttria, and magnesia spinel.

including alumina, mullite, zirconia, cordierite, yttria, and magnesia spinel.

*Please contact us for surface coatings, surface shapes, etc.

Physical Properties Chart

Firing jig/alumina-based

| Physical properties Unit Test methodProduct name Component |

016 | 106 | 115 | 214 | 202 | 201 | 314 | 663 | 683 | 632 | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al2O3 99.99% |

Al2O3 99.8% |

Al2O3 99.8% |

Al2O3 99.6% |

Al2O3 99.6% |

Al2O3 99.6% |

Al2O3 93% |

Al2O3 80% |

Al2O3 80% |

Al2O3 80% |

||||

|

Ceramic Properties

|

Bulk Specific Gravity JIS R2205 |

3.9 | 3.9 | 3.2 | 2.6 | 1.8 | 1.5 | 2.6 | 2.4 | 2.3 | 1.5 | ||

| Porosity(%) JIS R2205 |

0 | 0 | 11 | 35 | 55 | 63 | 28 | 29 | 30 | 56 | |||

| Bending Strength(MPa) *(1) JIS R1601 |

400 | 310 | 255 | 56 | 22 | 7 | 13 | 25 | 28 | 27 | |||

| Coeffcient of Thermal Expansion(×10-6) 100→1000℃ JIS R1618 |

8.1 | 7.8 | 7.8 | 8.0 | 8.2 | 8.3 | 6.0 | 5.2 | 5.5 | 5.4 | |||

| Thermal Conductivity 20℃(W/(m・k)) JIS R1611 |

32.5 | 34.3 | 18.0 | 12.0 | 6.5 | 4.4 | 4.1 | 2.1 | 2.5 | 1.3 | |||

| Specific Heat(J/(kg・K)) JIS R1611 |

0.77× 103 |

0.78× 103 |

0.76× 103 |

0.72× 103 |

0.71× 103 |

0.76× 103 |

0.75× 103 |

0.79× 103 |

0.71× 103 |

0.72× 103 |

|||

|

Independent Evaluation

|

Thermal Shock(℃) | 500 | 450 | 500 | 450 | 400 | 400 | 600 | 500 | 600 | 400 | ||

| Thermal Shock Limit Temperature(℃) | 620 | 560 | 530 | 460 | 380 | 450 | 520 | 650 | 690 | 630 | |||

| High temperature Bent(mm) | 1200℃ | - | - | - | - | 0.1 | 0.5 | - | - | - | - | ||

| 1300℃ | 0.1 | - | - | 0.1 | 0.9 | 4.9 | - | 0.2 | 0.1 | - | |||

| 1400℃ | 0.2 | 0.5 | 0.7 | 1.3 | 8.2 | 25㎜ or more | 0.1 | 0.5 | 0.4 | 0.2 | |||

| 1500℃ | 0.9 | 5.3 | 9.7 | 15.9 | 25㎜ or more | - | 0.2 | 2.3 | 1.2 | 1.4 | |||

| Characteristic | High purity product |

Highly dense, for powder metallurgy |

High multi-hole | General-purpose product for MIM | Porous for MIM | High porosity | Bent-resistant/spall-resistant | Mullite, general-purpose grade | Mullite | High porosity | |||

*The data are representative values, not guaranteed values.

*(1) 3-point bending test

Zirconia, yttria, spinel, cordierite

| Physical properties Unit Test methodProduct name Component |

827 | 837 | 835 | 923 | 922 | 915 | 933 | 951 | 961 | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ZrO2 Yttria-stabilized |

ZrO2 Calcia-stabilized |

ZrO2 Calcia-stabilized |

Y2O3 99.9% |

Y2O3 99.9% |

MgAl2O4 | MgAl2O4 | 2MgO 2Al2O3 5SiO2 |

2MgO 2Al2O3 5SiO2 +3Al2O3 2SiO2 |

||||

|

Ceramic Properties

|

Bulk Specific Gravity JIS R2205 |

4.1 | 4.2 | 3.3 | 2.2 | 2.0 | 3.3 | 2.4 | 1.2 | 1.3 | ||

| Porosity(%) JIS R2205 |

30 | 27 | 43 | 55 | 60 | 4 | 30 | 50 | 52 | |||

| Bending Strength(MPa) *(1) JIS R1601 |

96 | 18 | 22 | 18 | 7 | 160 | 60 | 20 | 15 | |||

| Coeffcient of Thermal Expansion(×10-6) 100→1000℃ JIS R1618 |

10.9 | 8.1 | 7.7 | 8.0 | 8.0 | 8.7 | 8.6 | 1.7 | 2.6 | |||

| Thermal Conductivity 20℃(W/(m・k)) JIS R1611 |

1.3 | 1.2 | 1.0 | 2.1 | 1.0 | 12 | 6.6 | 0.9 | 0.8 | |||

| Specific Heat(J/(kg・K)) JIS R1611 |

0.42× 103 |

0.43× 103 |

0.44× 103 |

0.42× 103 |

0.41× 103 |

0.79× 103 |

0.78× 103 |

0.71× 103 |

0.62× 103 |

|||

|

Independent Evaluation

|

Thermal Shock(℃) | 400 | 500 | 350 | 250 | 300 | 300 | 300 | 850 | 800 | ||

| Thermal Shock Limit Temperature(℃) | 540 | 300 | 440 | 480 | 400 | 490 | 410 | 1000 or more | 1000 or more | |||

| High temperature Bent(mm) | 1100℃ | 0.2 | 2.3 | 3.9 | - | - | - | - | 0.5 | 0 | ||

| 1200℃ | 1.0 | 6.3 | 10.8 | - | 0.3 | 0.2 | 0.4 | 25mm or more | 2.1 | |||

| 1300℃ | 2.5 | 18.1 | 25mm or more | 0.3 | 1.9 | 3.8 | 5.9 | - | 25mm or more | |||

| 1400℃ | 25mm or more | 25mm or more | - | 2.7 | 25mm or more | 25mm or more | 25mm or more | - | - | |||

| Characteristic | Y2O3 3mol SOFC |

CaO 4wt% for refractories |

CaO 4wt% for refractories |

general-purpose product | light-weight product | For firing basic, products high specific gravity | For firing basic, products high porosity | High thermal shock resistance | High temperature vent modification of 951 | |||

*The data are representative values, not guaranteed values.

*(1) 3-point bending test

*PDF will be displayed, so please click the print button.

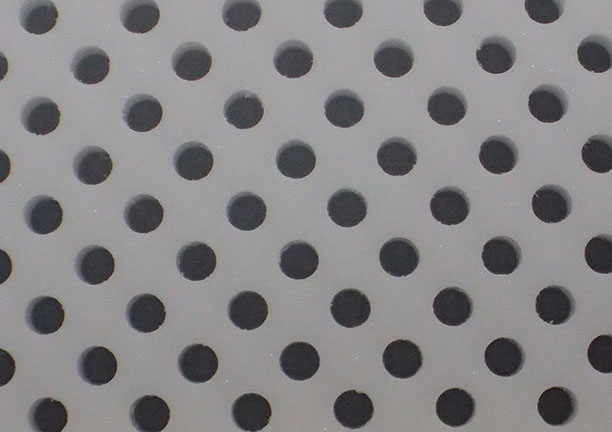

Multi-hole series MULTI-HOLE SERIES

Good gas displacement and degreasing.

Alumina and mullite are available.

Hole diameter, pitch, and shape, as well as zirconia coating are available.

Alumina and mullite are available.

Hole diameter, pitch, and shape, as well as zirconia coating are available.

Multi-hole series

| Physical properties Unit Test methodProduct name Component |

MH136 | MH215 | MH683 | |||

|---|---|---|---|---|---|---|

| Al2O3 99.8% |

Al2O3 99.6% |

Al2O3 80% |

||||

|

Ceramic Properties

|

Bulk Specific Gravity JIS R2205 |

3.9 | 3.2 | 2.3 | ||

| Porosity(%) JIS R2205 |

0 | 20 | 30 | |||

| Bending Strength(MPa) *(1) JIS R1601 |

392 | 103 | 28 | |||

| Coeffcient of Thermal Expansion(×10-6) 100→1000℃ JIS R1618 |

7.8 | 5.0 | 5.5 | |||

| Thermal Conductivity 20℃(W/(m・k)) JIS R1611 |

34.3 | 18.1 | 2.5 | |||

| Specific Heat(J/(kg・K)) JIS R1611 |

0.78× 103 |

0.62× 103 |

0.71× 103 |

|||

|

Independent Evaluation

|

Thermal Shock(℃) | 450 | 400 | 600 | ||

| Thermal Shock Limit Temperature(℃) | 560 | 460 | 690 | |||

| High temperature Bent(mm) | 1300℃ | - | 0.1 | 0.1 | ||

| 1400℃ | 0.5 | 0.8 | 0.4 | |||

| 1500℃ | 5.3 | 12.9 | 1.2 | |||

| Characteristic | Highly dense | porous | Mullite, porous | |||

*The data are representative values, not guaranteed values.

*Physical property data values do not include hole geometry.

*(1) 3-point bending test

*PDF will be displayed, so please click the print button.

*Click image to view larger image

| Product Name | MH136 |

|---|---|

| Material | Alumina |

| Composition | Alumina99.8% |

| Bulk Specific Gravity | Specific Gravity 3.90 |

| Porosity | 0% |

| Bending strength | 392MPa |

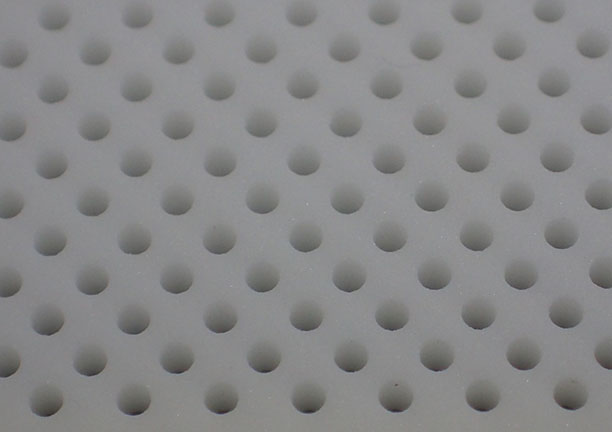

Breathable series BREATHABLE SERIES

This series features open pore structures using porous ceramics to reduce airflow resistance.

*Also available for filter and vacuum chuck applications.

*Also available for filter and vacuum chuck applications.

Air Permeable Series Physical Properties Table

| Physical properties Unit Test methodProduct name Component |

332 | 333 | 621 | 324 | ||||

|---|---|---|---|---|---|---|---|---|

| Al2O3 94% |

Al2O3 92% |

Al2O3 80% |

Al2O3 90% |

|||||

|

Ceramic Properties

|

Central Pore Diameter(μm) Mercury intrusion method |

10 | 26 | 60 | 13 | |||

| Porosity(%) JIS R2205 |

51 | 46 | 59 | 34 | ||||

| Bulk Specific Gravity JIS R2205 |

1.9 | 2.1 | 1.4 | 2.7 | ||||

| Bending Strength(MPa) *(1) JIS R1601 |

45 | 38 | 11 | 70 | ||||

| Coeffcient of Thermal Expansion(×10-6) 100→1000℃ JIS R1618 |

7.2 | 8.3 | 6.6 | 8.3 | ||||

|

Independent Evaluation

|

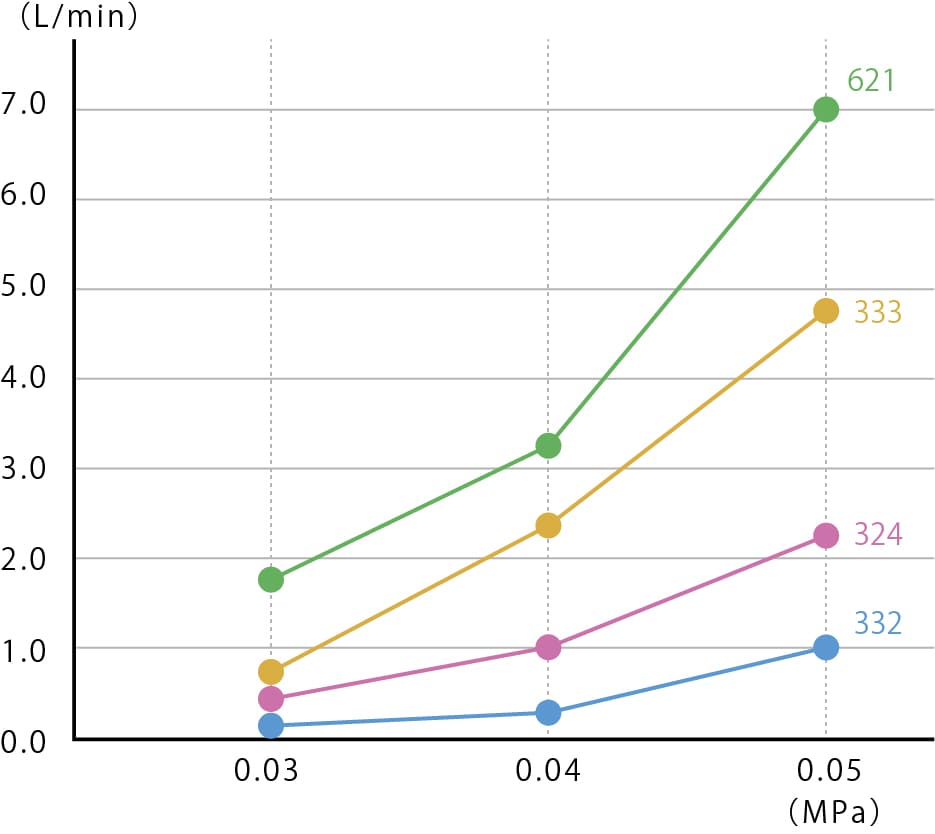

Air flow rate:0.05MPa(ℓ/min) Air pressure measurement |

1 | 4.7 | 6.9 | 2.3 | |||

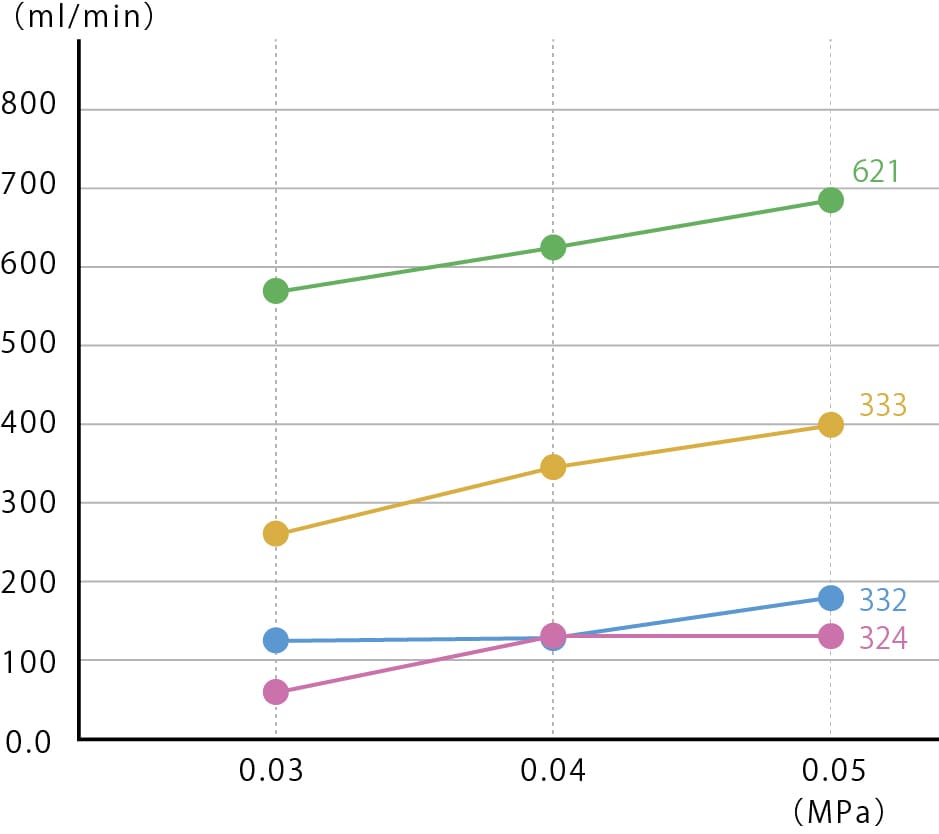

| Water flow rate:0.05MPa(㎖/min) Air pressure measurement |

177 | 404 | 690 | 124 | ||||

|

Corrosion rate

|

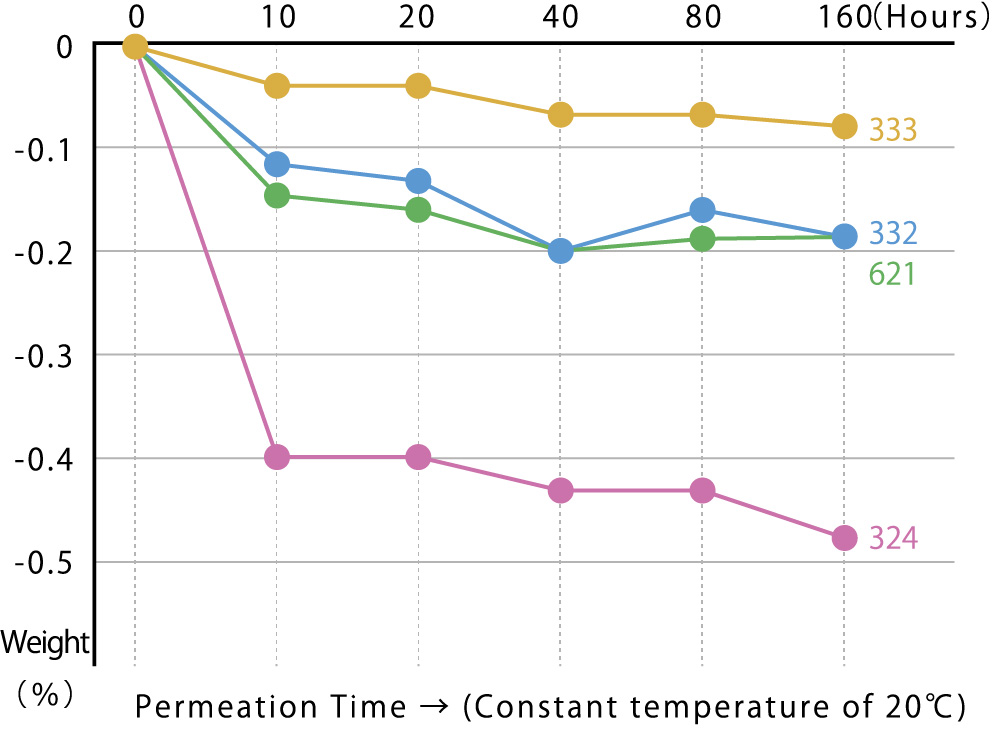

HNO3 20%(%) After immersion for 20 hours weight loss |

0.12 | 0.04 | 0.15 | 0.40 | |||

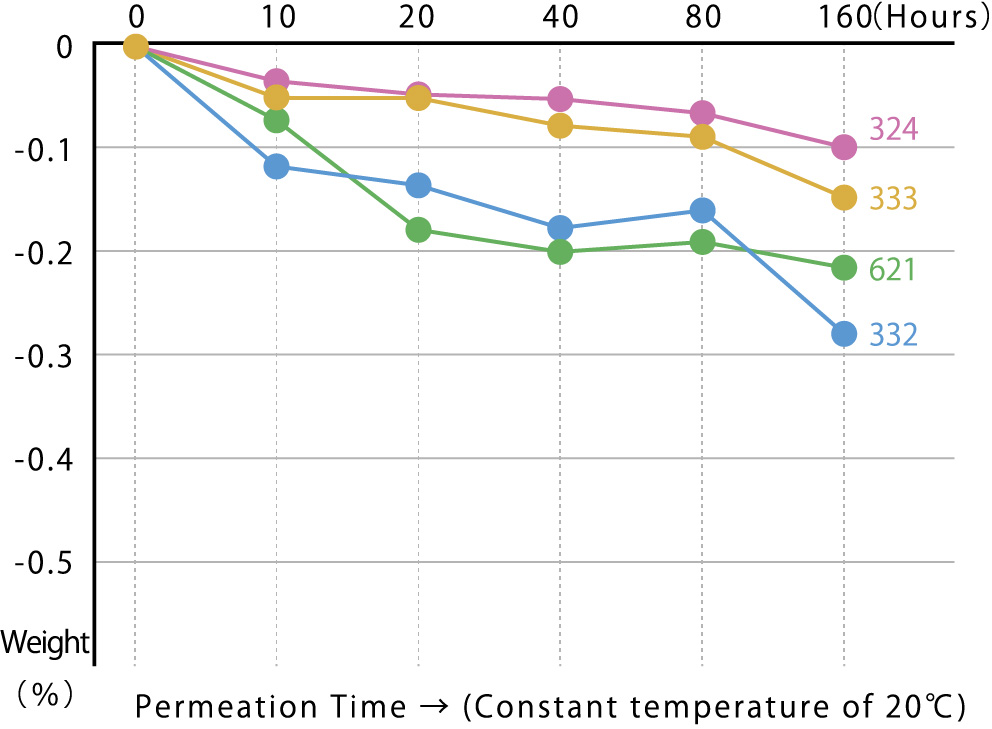

| NaOH 20%(%) After immersion for 20 hours weight loss |

0.13 | 0.05 | 0.17 | 0.04 | ||||

| Color | White | White | White | Black | ||||

*The data are representative values, not guaranteed values.

*(1) 3-point bending test.

Physical Properties Chart

Ventilation Volume

Water Flow Volume(Temperature 20℃)

Nitric Acid: 20% weight change

Sodium hydroxide:20% weight change

*PDF will be displayed, so please click the print button.

CONTACT USCONTACT US

For consultations and inquiries regarding our business and products, please contact us by phone or using the email form below.

5-15-10 Kakamihigashimachi, Kakamigahara City, Gifu Prefecture, Japan

TEL.

FAX.