Thermal shock・Thermal shock limit temperature

As an evaluation of superiority in quality, we have developed our own spall resistance test. and thermal shock limit temperature (thermal shock evaluation).

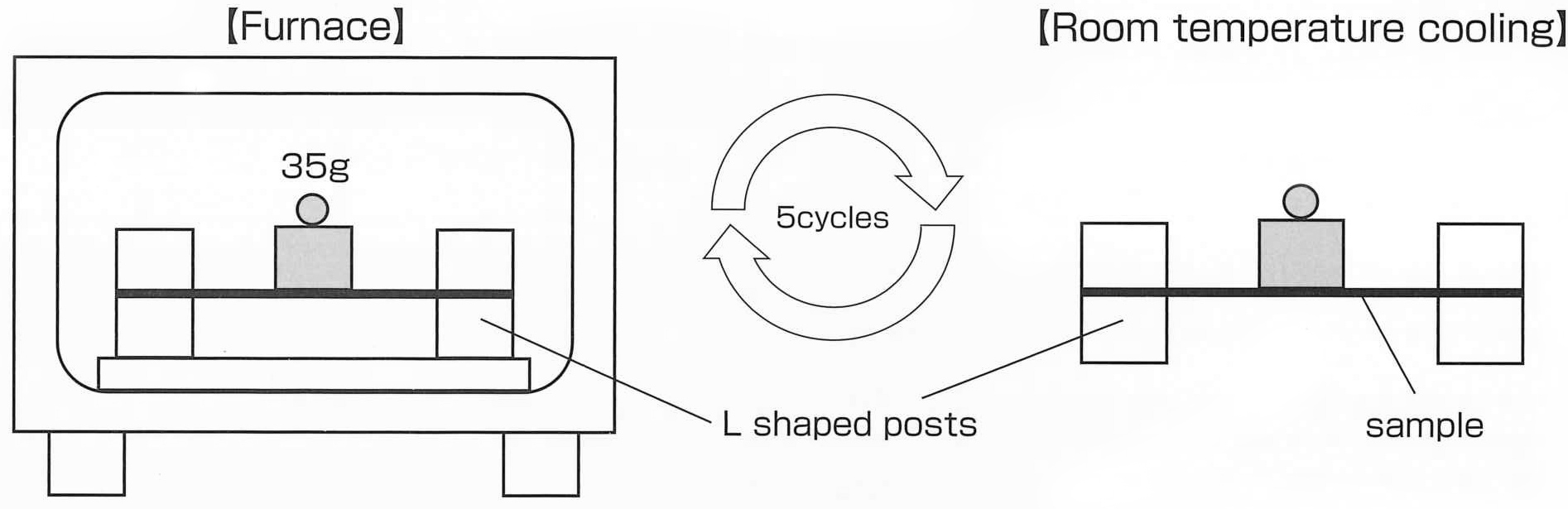

Thermal shock

The sample is quickly taken out to room temperature from the furnace adjusted to each temperature, cooled at room temperature, and quickly inserted into the furnace again. This cycle is repeated for 5 cycles.

The temperature is raised in increments of 50℃ if one sample does not crack, and the maximum value of the temperature range where cracking does not occur is the spall resistance temperature.

The temperature is raised in increments of 50℃ if one sample does not crack, and the maximum value of the temperature range where cracking does not occur is the spall resistance temperature.

Test condition

- Sample size

- 200×200×2(mm)

- Center load

- 35g

- Strut

- 25mm L-shaped posts at 4 corners

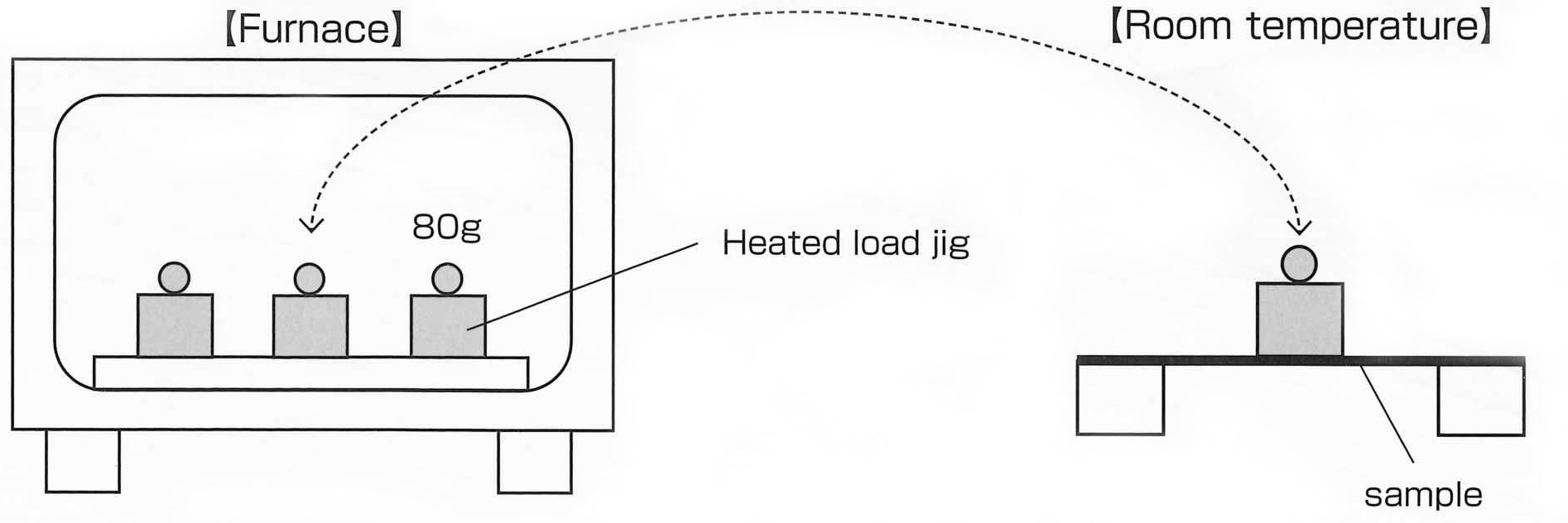

Thermal shock limit temperature

A heated load jig is placed in the center of the plate sample placed at room temperature to apply a thermal shock to the sample. A set of 5 samples per sample is performed in increments of 50℃ until all samples are cracked.The average temperature at which the sample cracks is taken as the thermal shock limit temperature.

Test condition

- Sample size

- 150×150×2(mm)

- Center load

- 80g

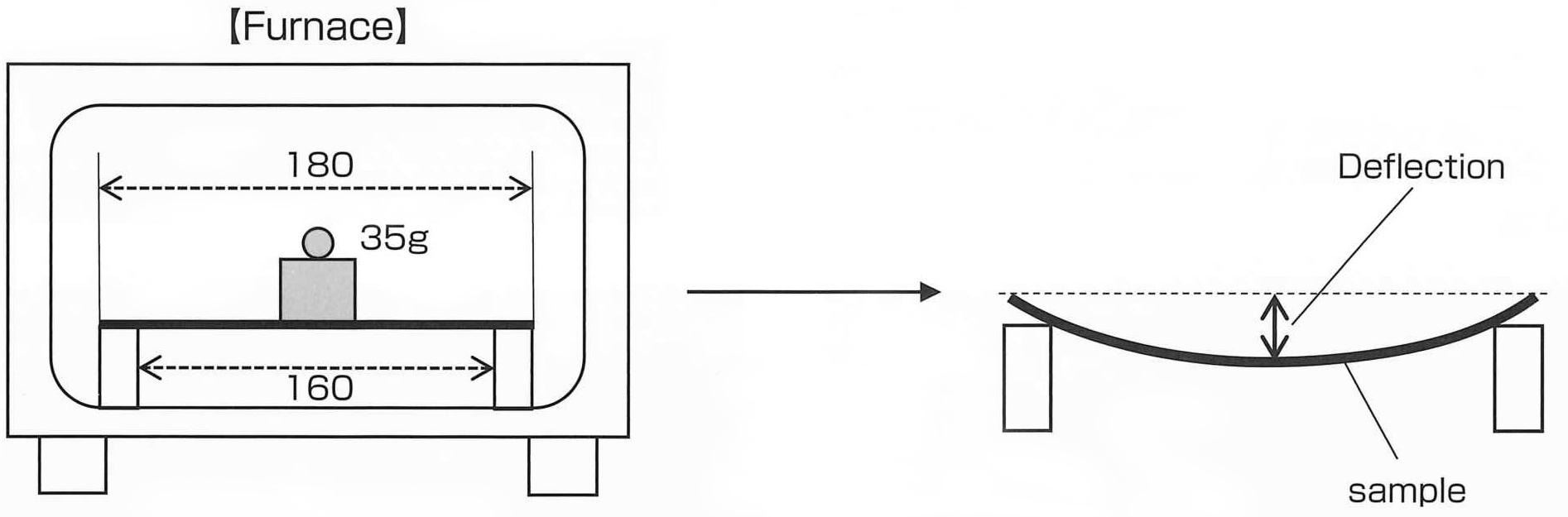

High temperature bent

At our company, as an evaluation of superiority in quality, we carry out a high temperature bent test (evaluation of deflection due to heat).

High temperature bent

After the heating test with a load applied at each temperature, the amount of sagging downward from the horizontal surface of the sample is measured with a dial gauge as the "deflection amount". The average value of the amount of deflection of the five sheets is taken as the result of that temperature.

Test condition

- Sample size

- 180×25×2(mm)

- Distance between fulcrums

- 160mm

- Keeping time

- 300minutes

- Center load

- 35g

CONTACT USCONTACT US

For consultations and inquiries regarding our business and products, please contact us by phone or using the email form below.

5-15-10 Kakamihigashimachi, Kakamigahara City, Gifu Prefecture, Japan

TEL.

FAX.