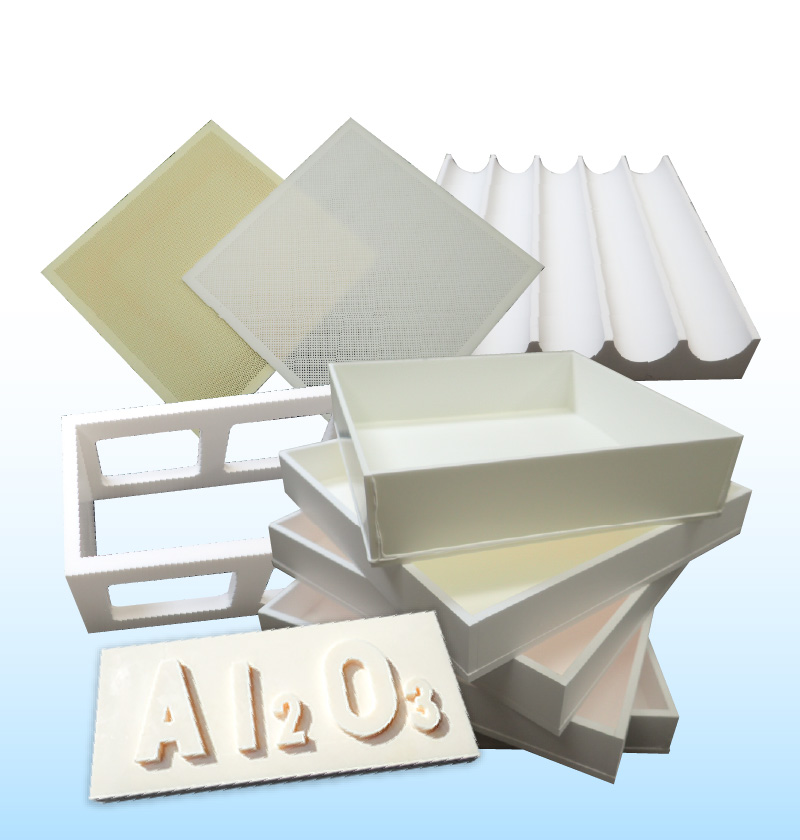

Firing Jigs SETTER

A wide variety of shapes, materials, and sizes are available to to ensure a good fit for your workpieces.

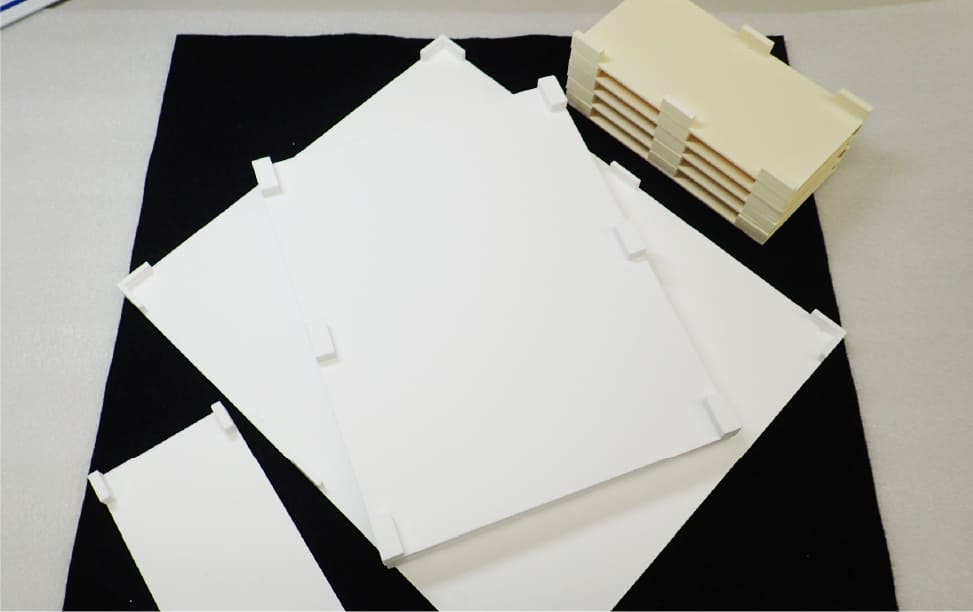

L Type Explanation

The setters can be used up to 1600 degrees because they utilize an inorganic adhesive to join flat plates and leg members made of the same material (4 to 8 pieces or more).

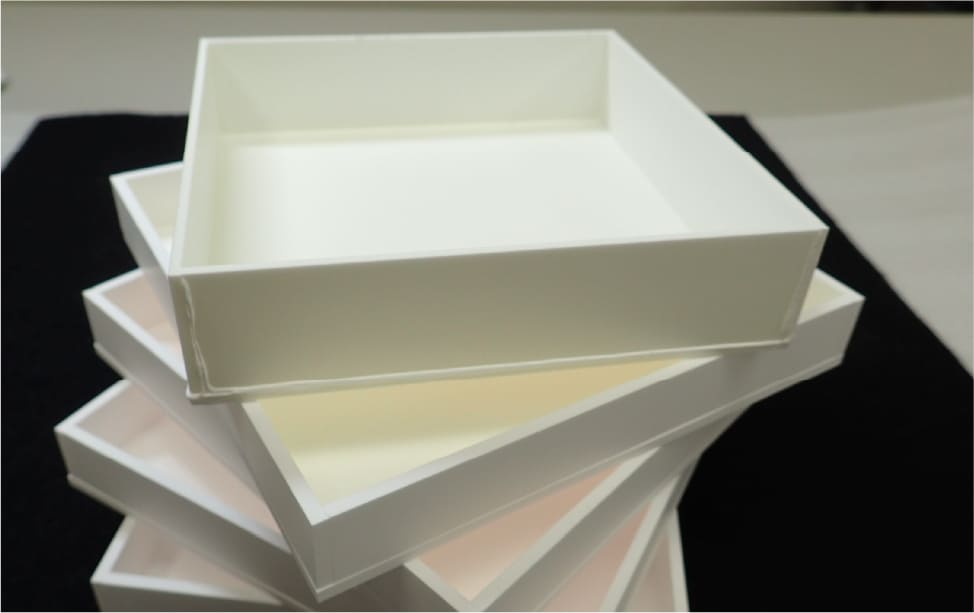

B Type Explanation

The setters can be used up to 1600 degrees because they utilize an inorganic adhesive to join flat plates and frame members made of the same material. In addition, by reinforcing the corners, they can also handle filling heavy items.

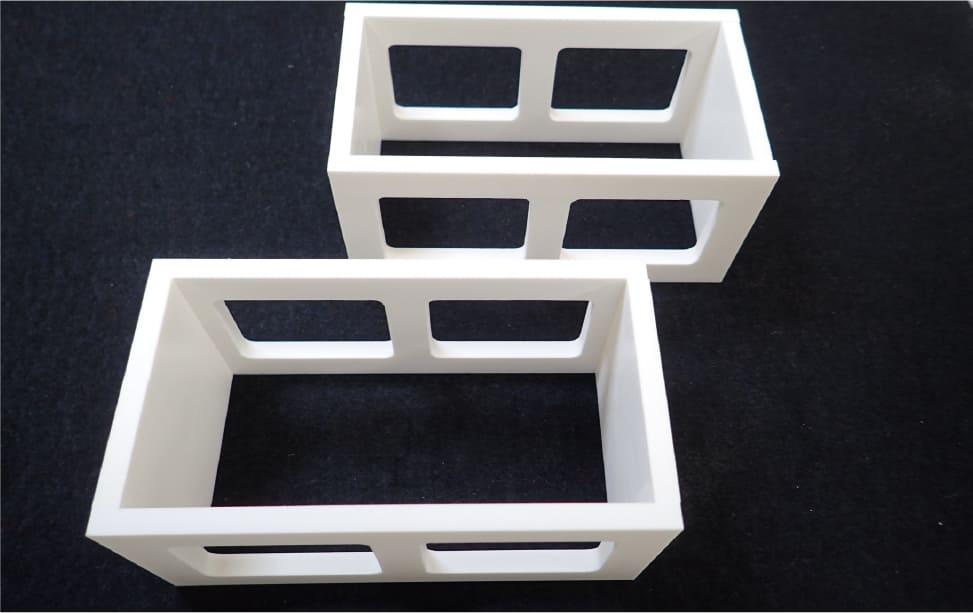

S Type Explanation

Used for well shapes, L-shapes, and square shapes that do not fit into the footed box category. We use the same bonding method, but depending on the shape, we may use stepped processing to increase the bonding area.

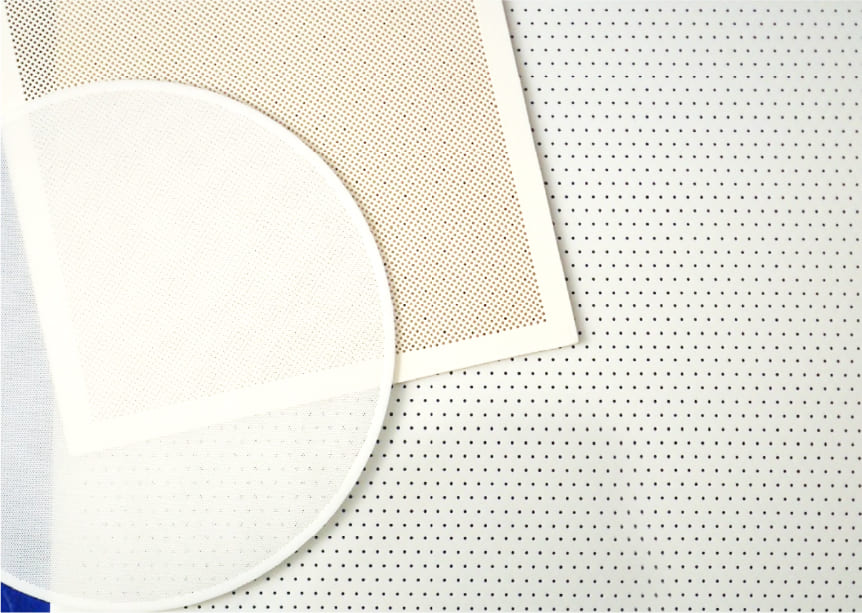

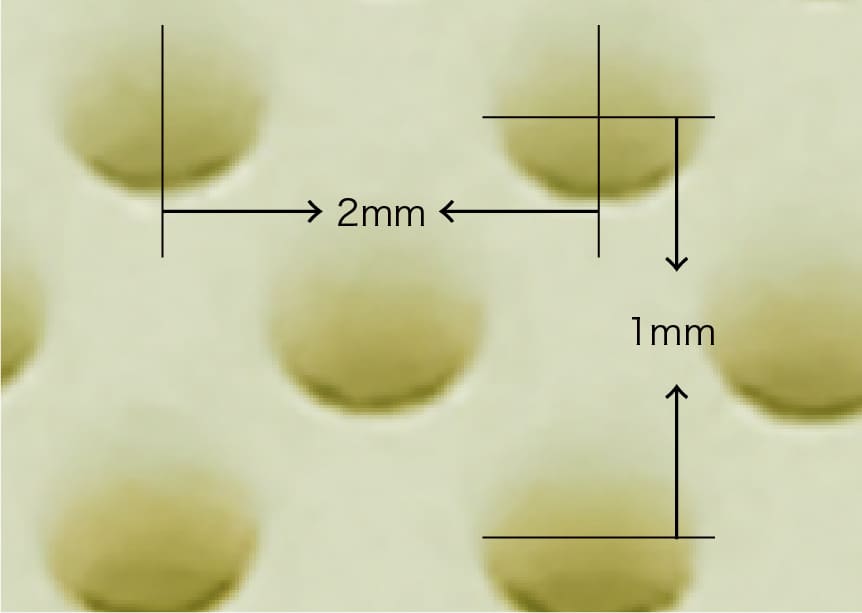

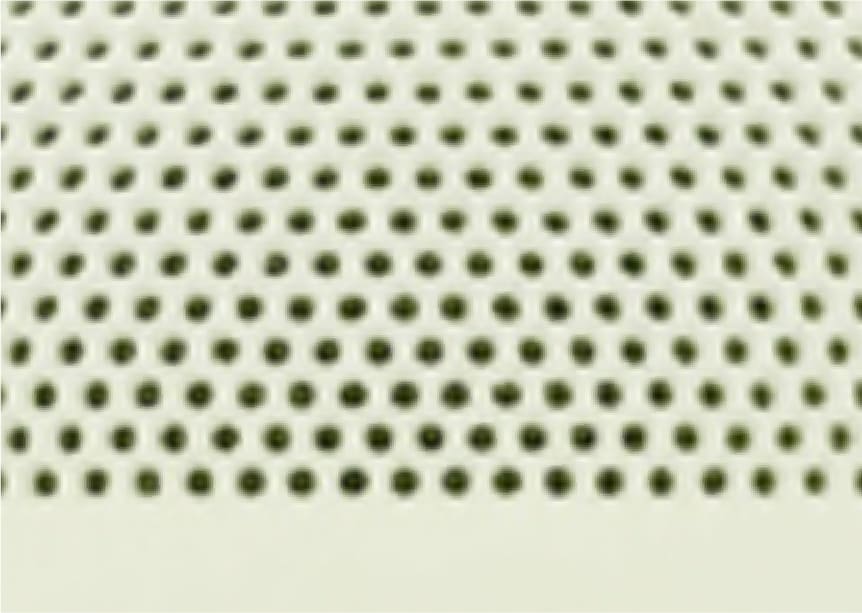

Multi-hole setter

Hole formation without machining

Using a unique method, we can create through holes with near-net molding.

Good outgassing

Good gas displacement and degreasing.

Material: We offer alumina, mullite, and zirconia coating

No reactivity with workpieces.

Size: Free usage

Hole diameter and pitch, etc., can be changed.

Latest Product Information

Surface Coating Yttria-stabilized zirconia Z Series

NEW Molding Technology

New Form of Fine Ceramics

We have added a new line of zirconia coated products to our popular lineup.

The raw materials used in our manufacturing process are different from those used in conventional products, are will reduce the frequency at which you need to replace parts.

The raw materials used in our manufacturing process are different from those used in conventional products, are will reduce the frequency at which you need to replace parts.

It contains even less SiO2 than Z2 and is effective in preventing reactions with the Ni-Zr compounds, metal oxides, etc. used in SOFCs.

It contains even less SiO2 than Z2 and is effective in preventing reactions with the Ni-Zr compounds, metal oxides, etc. used in SOFCs.

| Coating Code | Z | Z2 | Z3 | Z4 | ZY | YY | ||

|---|---|---|---|---|---|---|---|---|

|

Coating Properties

|

Main Component | ZrO2 Yttria-stabilized |

ZrO2 Yttria-stabilized |

Y2O3 | ||||

| Bulk Specific Gravity | 3.7 | 4.2 | 3.8 | 3.4 | - | - | ||

| Porosity(%) | 36 | 30 | 29 | 41 | - | - | ||

|

Coat Component

|

ZrO2 | % | 91.0 | 91.8 | 84.4 | 90.8 | 91.8 | - |

| Y2O3 | 8.0 | 7.9 | 15.5 | 8.1 | 8.0 | 99.9 | ||

| CaO | 0.24 | 0.09 | - | 0.39 | - | - | ||

| SiO2 | 0.24 | 0.07 | <0.01 | 0.06 | <0.01 | - | ||

| Al2O3 | 0.30 | - | 0.07 | 0.13 | 0.05 | - | ||

| TiO2 | 0.20 | 0.10 | 0.02 | 0.13 | 0.09 | - | ||

| Fe2O3 | 0.05 | 0.06 | 0.01 | 0.04 | 0.01 | 0.05 | ||

| Coatable materials | alumina, mullite | alumina, mullite, cordierite | mullite | alumina, mullite | 115 214 663 |

115 214 |

||

| Coating Method | Spraying + Sintering | Thermal spraying | ||||||

*The data are representative values, not guaranteed values.

CONTACT USCONTACT US

For consultations and inquiries regarding our business and products, please contact us by phone or using the email form below.

5-15-10 Kakamihigashimachi, Kakamigahara City, Gifu Prefecture, Japan